According to the BMUV, the fashion industry represents a quarter of all online trade. Apart from the fact that the production of new items of clothing is one of the biggest climate killers anyway, the items produced are then also sent around the world individually packaged in plastic bags. These plastic bags – or polybags – are not very sustainable, but they are essential due to the way they work. As the call for sustainability in all areas and a reduction in plastic consumption is getting louder and louder, there are now numerous supposedly sustainable alternatives. We have put these together for you in Fashion e-Commerce and looked at the extent to which these alternatives are really so much more sustainable, or whether it’s more about greenwashing.

Content of this article:

What exactly are polybags?

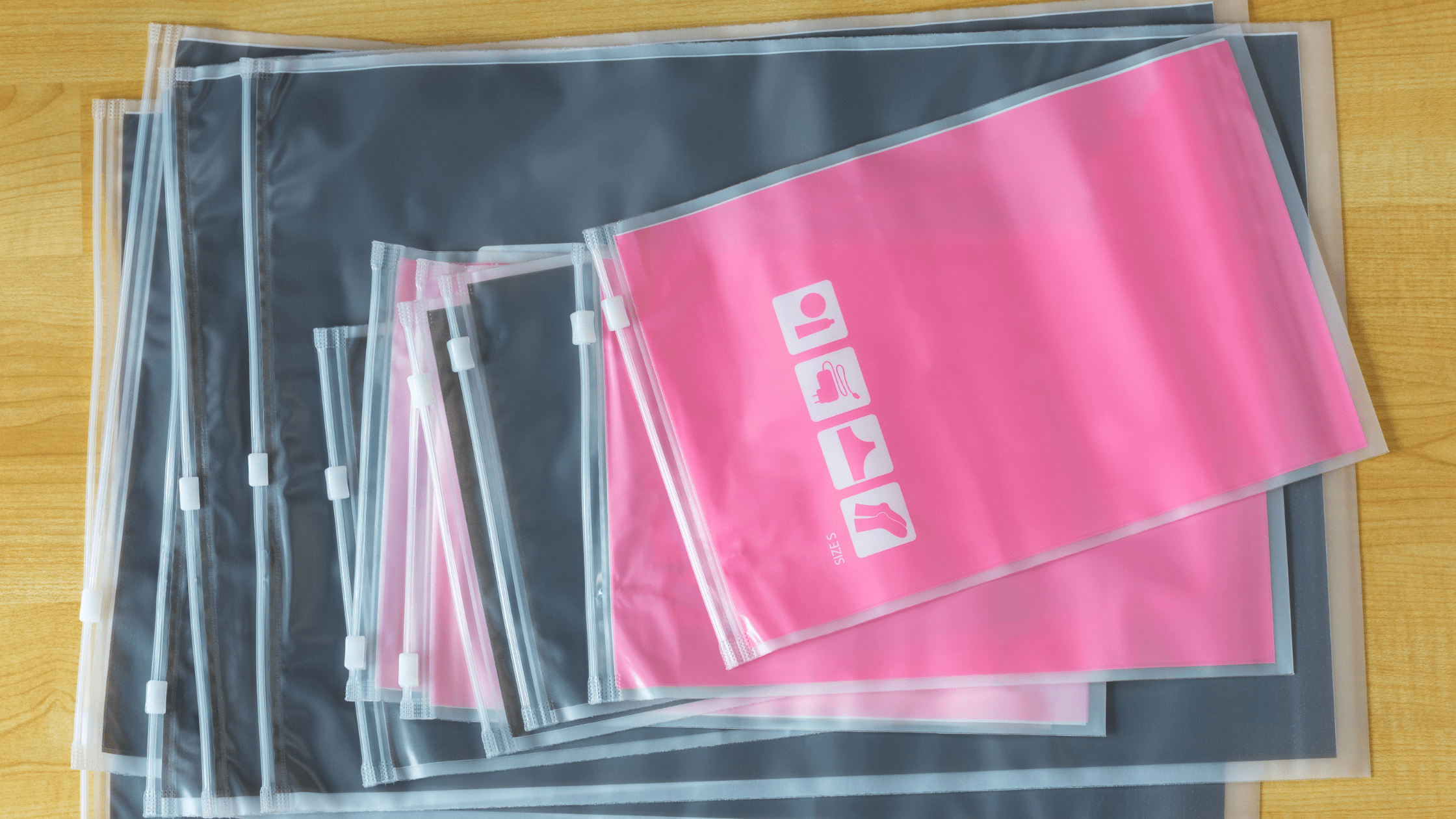

Most people will be familiar with them. Polybags are simple, transparent plastic bags or packaging. They are made of plastic or synthetic material, i.e. polyethylene (PE) or polypropylene (PP) – hence the name polybag.

They are used to transport purchases or to store garbage, but also to protect products during shipping. While plastic bags are no longer used in supermarkets, hardly any items arrive in online shops without a plastic bag. Clothing in particular is shipped in these transparent plastic bags. They therefore play a very important role in fashion e-commerce.

Why are polybags so important for fashion e-commerce?

Polybags play an important role in online retail in general, but even more so in fashion e-commerce. They combine numerous important functions and are also inexpensive.

The following functions are particularly important for the shipping of clothing and a smooth supply chain:

Protection:

The products are individually packed in bags and are therefore optimally protected. This is particularly important for long supply chains, for example from Asia to Europe. The plastic packaging not only protects them from dust and dirt but also from moisture, which is extremely important for textiles.

Transport:

Analogous to this is the transportation function. Polybags are light and take up little space. This is particularly important, as transportation is charged according to weight and mass. If packaging takes up a lot of additional space or weighs a lot, this means additional costs and less space for the actual products.

It is also important for transportation that the polybags are tear-resistant. This means that the products are not damaged and the processes along the supply chain are not disrupted by faulty and destroyed packaging.

Transparency and information:

Polybags used in fashion e-commerce for shipping clothing are transparent. This is incredibly practical, as you can always see which product is in the bag. In addition, labels or so-called hangtags are attached to the items of clothing.

What are the main problems with using polybags?

Of course, there are still problems with the use of polybags in fashion e-commerce.

The very high volume of waste is particularly critical. Each item is packed individually and then often re-packed with other individually packed items. This creates a lot of waste. In normal fashion retail, this packaging waste is generated in one place – when unpacking in the stores. Here, the plastic could at least be collected in one place and recycled more easily. This is not so easy when shipping online, which also makes it more difficult to recycle the bags. They cannot be collected and processed separately. Furthermore, stickers, imprints, staples and the like cause contamination during recycling.

Why are they still used?

The ecological impact of polybags is lower than that of a product that has become unusable. For this reason, it makes more sense to use polybags instead of accepting that some of the products become unusable even before they reach the customer (consumption of water, resources, etc.) (source).

The use of polybags is therefore out of the question for many companies in fashion e-commerce. However, there are now supposedly sustainable alternatives to the “standard plastic polybag”.

What types of polybags are there and ho sustainable are they really?

“Standard” polybags made from conventional plastic

These are made of low-density polyethylene (LDPE) – or rarely of high-density polyethylene (HDPE). Polyethylene is obtained from petroleum or natural gas. This is refined and split and then pressed into pellets. These are processed into plastic products.

Pro:

- fulfills all the important functions for fashion e-commerce

- cheap – one bag usually costs no more than €0.10.

Cons:

- Sustainability in production.

- Problems with recycling

- CO2 emissions during production

- High consumption of resources – especially fossil raw materials

Polybags made from recycled material (recycled polybags)

As the name suggests, they are made from recycled material. Old plastic waste that is collected, for example, via the yellow bag, is separated and processed into granulate (recyclate) in a reprocessing process, which can then be used to produce new bags.

Pro:

- Removes plastic from the waste stream by recycling it

- Reduces the demand for fossil raw materials and lowers CO2 emissions

Cons:

- Requires plastics that need to be recycled or produced for this purpose as the recycling process cannot be repeated indefinitely

- The price is higher than for new plastic

- The quality and purity of the recycled material is impaired by admixtures and impurities from stickers and printing.

Reusable polybags

As the name suggests, these are classic polybags that are intended to be used several times without their functions being restricted or impaired by reuse.

Pros:

- Reduction in the amount of plastic

- Reducing plastic waste in the environment

Cons:

- Must be resealable and robust, which means they must be made of thicker material, which means fewer products can be packaged and they weigh more

- The bags have to be returned to the production site to be used again, which is a major logistical challenge and also not ideal for the environmental balance sheet

Polybags made from bioplastics

At 1.3%, bioplastics still account for a small proportion of global plastics production. Bioplastics are biodegradable, biobased or both.

In this case, biobased means that the material or product was (at least partially) produced from biomass – i.e. plants or animals. Corn, sugar cane or cellulose are used here, for example.

Biodegradable or compostable means that the material can be converted into natural substances such as water, carbon dioxide and compost by means of a chemical process with the help of microorganisms. These microorganisms should be present in the environment and the process should be able to take place without artificial additives. The environmental conditions – location, temperature, material and applications – are also decisive for this. These often consist of PLA plastics, i.e. polyactide acid. The problem with this is that the environmental conditions required for them to biodegrade are very rare in reality. They must therefore be disposed of in residual waste, not in organic waste, and can cause major damage to nature.

All plastics can therefore be divided into four groups, each with two characteristics:

a) Raw material basis – renewable/organic or fossil

b) Degradability – biodegradable or non-biodegradable

Conventional polybags made from polyethylene or recycled material are therefore not biodegradable and are made from fossil raw materials.

In general, the following advantages and disadvantages apply to bioplastics:

Pros:

- Properties of most of these polybags are comparable to those of conventional ones

Cons:

- Cost. The price is currently comparatively high

- Cannot currently be recycled in most cases, therefore placed below conventional bags in the waste hierarchy

- Disruptive factor in the recycling process of conventional plastics

- Customer ignorance about composition and use can lead to increased use of plastic

- “False good feeling” because bioplastics are used – avoiding plastic altogether is considered less urgent

However, the following should be added for plastics made from renewable raw materials:

Opportunities:

- They reduce the overall demand for fossil raw materials

- Reduce CO2 emissions

Risks:

- Competition for arable land – land is needed for the cultivation of these materials, which cannot be used for food production

- Components from fossil raw materials are often added

There are also corresponding opportunities and risks for biodegradable plastics.

Opportunities:

- The introduction of plastic into the environment is reduced

Risks:

- Misunderstandings about biodegradability

- Confusion with other types of plastic, which could lead to

Polybags made from recycled paper

Paper is often seen as more ecological than plastic, but this is not necessarily the case, as its production also has a major impact on the environment. Not only does it require large quantities of wood, water and energy, but also harmful chemicals. This means that it definitely performs worse than bioplastics or recycled plastic. If recycled paper were used, the environmental impact would be significantly reduced and would be the best solution in purely ecological terms.

Pros:

- Recycled paper is compostable

- Recycling structures exist in most countries

- Does not harm nature as it is biodegradable

Cons:

- Logistical requirements and functions cannot be fulfilled in some cases due to a lack of transparency, robustness and protection against moisture

- Marketplaces or fulfillment service providers often do not accept them as a result

What developments and opportunities are there for fashion e-commerce?

The fact is that plastic consumption in textile retail and especially fashion e-commerce must be reduced.

There is also a trend among consumers towards more sustainable packaging. A majority would even approve of a reusable packaging system in general and pay a deposit for reusable transport boxes.

What can companies in fashion e-commerce do?

Here are a few thoughts and ideas that can help you on your way to greater sustainability.

Increase the recyclability of standard LDPE polybags:

There are a few things to consider so that the standard polybags used can be easily recycled afterward. Paper, stickers, adhesives and labeling, for example, make this more complicated. The “purer” the material, the easier.

Research and adapt alternative materials:

Knowledge is power. What are the bags in the company made of? Are there options for using other materials? Asking yourself these questions can often help you to initiate changes and see that they are not so complicated and complex. There are now numerous polybag alternatives on offer.

Certificates for compostability:

Of course, these numerous offers of alternatives can also be confusing. What does “bio-based” mean compared to “bioplastic” or “compostable”? You can find an overview of the certified terms here (page 26).

Reduce the amount of waste:

The easiest way could be to reduce the volume and number of polybags used. One option would be to pack more clothing in larger bags over the long transportation routes. And/or folding clothes smaller so that less material is needed.

However, there is no question that all types of polybags must be registered as waste in your destination countries – and not just the packaging itself, by the way, as many EU countries now also have guidelines on textile EPR.

We can explain to you what these are and in which countries you have to register your waste and how!

More interesting articles for you:

EU Textile EPR Directive for Fashion Brands

New EU packaging regulation: what does it mean for e-commerce?